PRODUCTION PROCESS

Specialized procedures

for maximum fruit yield

Step 1

Receiving the fruit

The olive fruit is received in canvas sacks at the olive mill site by the producers every day after the end of the harvest. It is temporarily stored until it is time to process.

Step 2

Washing and weighing

In the first stage of processing, the olives are washed and separated from leaves and foreign matter. Immediately afterwards they are weighed before moving on to the next phase.

Step 3

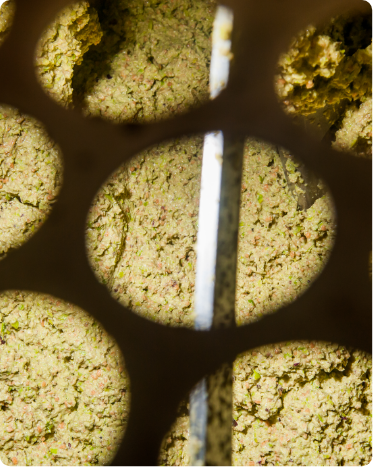

Crushing and kneading

In the next stage the olives enter the crusher. There they are crushed and then the pulp created is sent to the softener. In the blender it will be heated to a maximum of 27°C and stirred for about 30 minutes

Step 4

Separation of olive oil

In the third stage, the oleoferment is sent to the horizontal separator (Decanter). There the olive oil will be separated from the core.

This process is called “Separation of two phases” as olive oil and core are extracted together with the rest of the fruit’s liquids. It is the most ecological process because it does not produce waste as the core ends up in a nuclear plant for the production of kernel oil and heartwood for domestic and industrial heating.

Step 5

Clarification of olive oil

In the third stage, the oleoferment is sent to the horizontal separator (Decanter). There the olive oil will be separated from the core.

In the last stage, the olive oil is continuously fed to the vertical separator along with a minimum of water at a maximum temperature of 27°C. This will help in the final separation of the olive oil from water and foreign matter.

Discover the place that gives birth to quality

The geographical location of the Olive Mill in the fertile land of Messinia, combined with its modern facilities, allows it to serve a large number of olive producers from all over Greece.